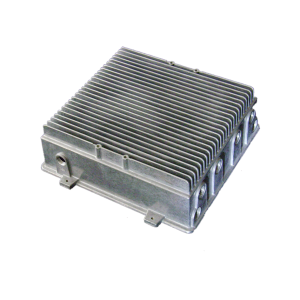

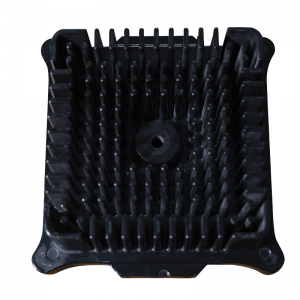

Nwunye mkpuchi aluminom heatsink nke igbe eletrik

Nkedo anwụ bụ usoro nrụpụta nke ọma nke nwere ike imepụta akụkụ nwere ụdị dị mgbagwoju anya.Site na nkedo anwụ, enwere ike itinye nku ọkụ ọkụ n'ime etiti, ụlọ ma ọ bụ ihe mkpuchi, ya mere enwere ike ibufe ọkụ ozugbo site na isi iyi gaa na gburugburu ebe obibi na-enweghị ihe mgbochi ọzọ.Mgbe ejiri ya mee ihe n'ụzọ zuru oke, nkedo anwụ na-enye ọ bụghị naanị arụmọrụ ọkụ dị mma, kamakwa nnukwu ego na-akwụ ụgwọ.

Uru nke Nkedo Aluminom Heatsink

Uru ma ọ bụ adịghị ike nke heatsink nkedo anwụ na-adabere n'ụdị ihe eji emepụta ya.Dịka ọmụmaatụ, aluminom bụ ihe a na-ejikarị eme ihe iji mepụta heatsinks nkedo anwụ.Ụfọdụ uru dị mkpa nke heatsinks die-cast bụ edepụtara n'okpuru:

1.Nke mbụ, ị ga-achọpụta na ndị na-anwụ anwụ na-arụ ọrụ nke ọma maka ngwaọrụ eletrik.

2.Die nkedo okpomọkụ na-agụnye usoro nkedo, n'ihi ya, ha nwere ike ịdị n'ụdị buru ibu.

3.Fins nke heatsinks na-anwụ anwụ nwere ike ịdị na oghere dị iche iche, ụdị, na nha.

4.There na-ebelata mgbagwoju anya na anwụ-nkedo heatsink aghụghọ.N'ihi ya, enwere mkpa iji rụọ ọrụ igwe.

5.Ị nwere ike ịgbakwunye ọwa dị iche iche iji kpochapụ okpomọkụ site na ikpo ọkụ ọkụ na-anwụ anwụ.

6.Die cast heatsinks dị ọnụ ala ma nwee ike ree ya na nnukwu mpịakọta.

7.Ị nwere ike inwe ọtụtụ nhazi ngwaahịa na heatsinks na-anwụ anwụ.N'agbanyeghị ihe nghazi nke components bụ, a na-edobe okpomọkụ nke ọma.

8.Manufacturers nwekwara ike hazie die-nkedo heatsinks dị ka gị chọrọ.

Tebulu ọdịnaya

Nhazi nkedo aluminiomu kacha mma: Imepụta maka nrụpụta(DFM)

9 Aluminom Die Nlebanya Ntube Ntube Ka Iburu n'uche:

1. Ahịrị nkebi 2.Ejector atụdo 3. Mbelata 4. Draft 5. Ọkpụrụkpụ mgbidi

6. Fillets na Radii7. Ndị isi 8. Ribs 9. Undercuts 10. Oghere na windo