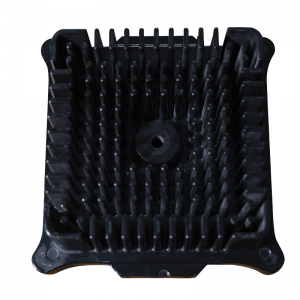

heatsink omenala anwụ-nkedo maka Radiator

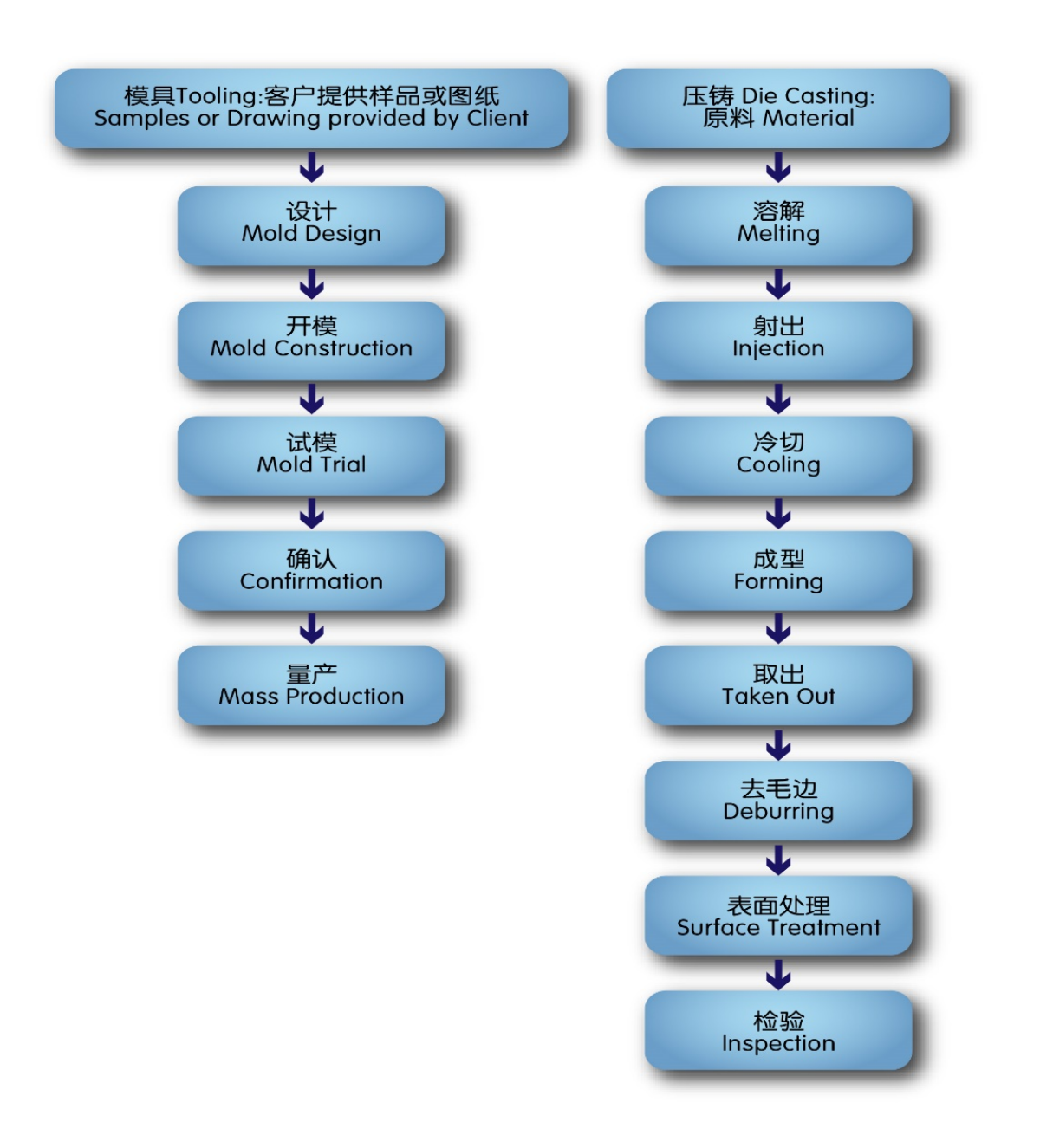

Usoro nke ikpo ọkụ

Nhazi ngwaọrụ

Nnukwu nrụgide anwụ nkedo

Mbelata

Deburding

Mgbawa aja

Nchacha elu

Mkpuchi ntụ ntụ

CNC ịkụ aka & igwe

Ntinye Helical

Ọgwụgwọ elu

1. Chemical oxidation

2. Ihe osise

3. Electrophoresis

4. Anodizing

5. mkpuchi ntụ ntụ

Ọnwụ nkedo okpomọkụ imi

Ọnwụ nkedo okpomọkụ zuru oke ma ọ bụrụ na ị chọrọ omenala a haziri aluminom okpomọkụ sink.A na-emepụta ha site na ịmanye aluminum mmiri mmiri n'okpuru nrụgide dị elu n'ime ihe nchara ígwè .Die nkedo okpomọkụ na-ewu ewu na ahịa n'ihi na e si na aluminom alloy mee ya.Nke a bụ ihe a na-ahọrọ maka ikpo ọkụ anwụ anwụ.Usoro nkedo ịnwụ anwụ ndị a dabara adaba iji mezuo ihe ngo ọ bụla achọrọ wee rụpụta ngwa ngwa.

Oge ndu ngwa ngwa naanị ụbọchị 35-40

High Performance na anodized elu agwụ

A na-achịkwa akụkụ siri ike dị elu n'ime +/- 0.05mm

Ndị injinia na-enyere aka mechaa site na imewe ruo n'ichepụta

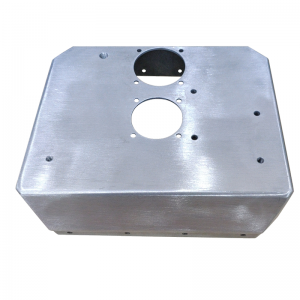

Uru Ọkụ Ọkụ Ọnwụ anwụ

Tụnyere usoro nrụpụta ndị ọzọ, nkedo anwụ na-enye uru ndị a:

1.Produce mgbagwoju 3D shapes na-agaghị ekwe omume na extrusion ma ọ bụ forging

Igwe ọkụ aluminom, etiti, ụlọ, ihe mkpuchi na ihe mgbakwunye nwere ike jikọta n'otu nkedo

2.Oghere nwere ike ịdekọ na nkedo anwụ

3.High mmepụta ọnụego na ọnụ ala

4.Tight tolerances

5.Dimensionally kwụsiri ike

6. Secondary machining achọghị

Nye ebe dị larịị pụrụ iche (ọ dị mma maka kọntaktị dị n'etiti ikpo ọkụ na isi iyi)

Nguzogide corrosion na-esi na nke ọma ruo elu

Usoro usoro Kingrun

Tụnyere usoro nrụpụta ndị ọzọ, nkedo anwụ na-enye uru ndị a:

1.Produce mgbagwoju 3D shapes na-agaghị ekwe omume na extrusion ma ọ bụ forging

Igwe ọkụ, etiti, ụlọ, ihe mkpuchi na ihe mgbakwunye nwere ike ijikọ n'otu nkedo

2.Oghere nwere ike ịdekọ na nkedo anwụ

3.High mmepụta ọnụego na ọnụ ala

4.Tight tolerances

5.Dimensionally kwụsiri ike

6. Secondary machining achọghị

Nye ebe dị larịị pụrụ iche (ọ dị mma maka kọntaktị dị n'etiti ikpo ọkụ na isi iyi)

Nguzogide corrosion na-esi na nke ọma ruo elu

Ezigbo EMI ihe nchekwa RFI