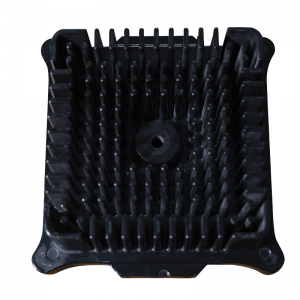

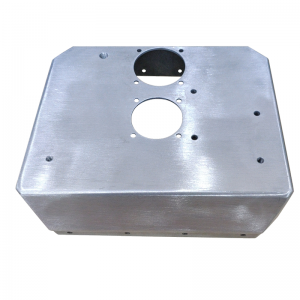

Heatsink omenala nke a na-akpọ Die-cast maka Radiator

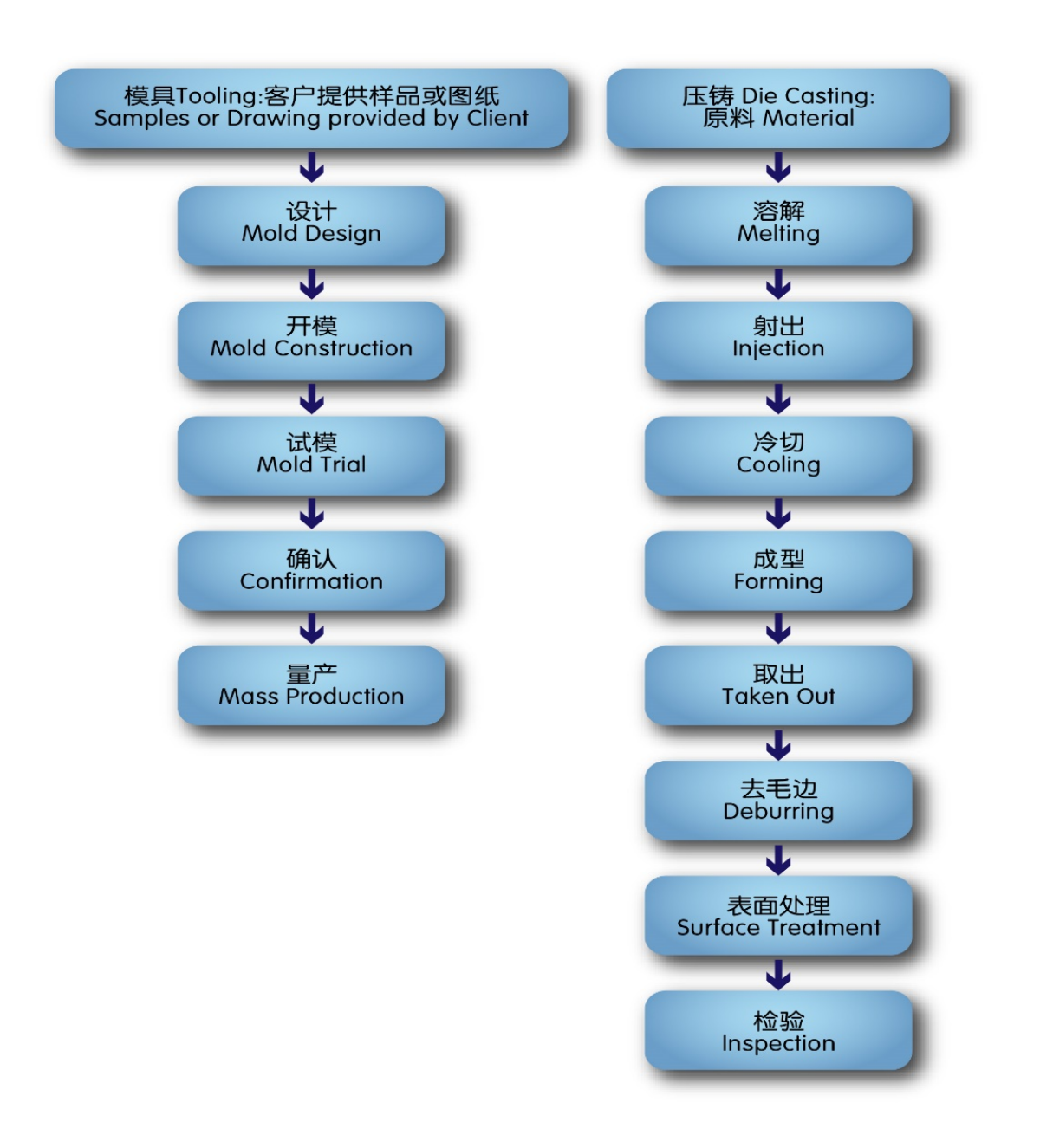

Usoro nke sink okpomọkụ

Nhazi ngwaọrụ

Ịgba ígwè nrụgide dị elu

Ịkpụcha ihe

Ịkwapụ ihe mkpofu

Ịfụ ájá

Ịchacha elu

Mkpuchi ntụ ntụ

Ịmepụta na imecha CNC

Ntinye helikal

Ọgwụgwọ Elu

1. Oxidation kemịkalụ

2. Ịse ihe osise

3. Electrophoresis

4. Ịmepụta Anodizing

5. Mkpuchi ntụ ntụ

Sinks okpomọkụ a kpụrụ akpụ

Ebe a na-etinye ihe na-ekpo ọkụ nke a na-akpọ "Die cast Heat Sinks" zuru oke ma ọ bụrụ na ịchọrọ ebe a na-etinye ihe na-ekpo ọkụ nke aluminom. A na-emepụta ha site n'ịmanye aluminom mmiri mmiri n'okpuru nrụgide dị elu n'ime ebu ígwè. Ebe a na-etinye ihe na-ekpo ọkụ nke a na-akpọ "Die cast Heat Sinks" na-ewu ewu n'ahịa n'ihi na e ji aluminom alloy mee ya. Nke a bụ ihe a na-ahọrọ maka ebe a na-etinye ihe na-ekpo ọkụ nke a na-akpọ "Die cast Heat Sinks". Usoro ndị a dabara adaba iji mezuo ihe niile achọrọ maka ọrụ ma rụọ ọrụ ngwa ngwa.

Oge mbufe ngwa ngwa naanị ụbọchị 35-40

Arụmọrụ dị elu na njedebe elu anodized

Akụkụ siri ike dị elu nke a na-achịkwa n'ime +/-0.05mm

Ndị injinia na-enyere aka imecha site na imewe ruo na nrụpụta

Uru nke Die Cast Okpomọkụ Sinks

Ma e jiri ya tụnyere ụzọ ndị ọzọ e si emepụta ihe, ihe ndị a na-eme ka ihe dị n'ime ya na-enye uru ndị a:

1. Mepụta ụdị 3D dị mgbagwoju anya nke na-agaghị ekwe omume na mpụta ma ọ bụ imepụta ihe

Enwere ike ijikọta ihe na-ekpo ọkụ aluminom, etiti, ụlọ, ihe mkpuchi na ihe ndị na-ejikọ ọnụ n'otu nkedo

2. Enwere ike itinye oghere n'ime nkedo anwụ

3. Ọnụego mmepụta dị elu na ọnụ ala dị ala

4.Nchedo siri ike

5. N'akụkụ kwụsiri ike

6. Achọghị igwe eji arụ ọrụ nke abụọ

Nye elu dị larịị nke ukwuu (ọ dị mma maka kọntaktị n'etiti ebe a na-ekpo ọkụ na ebe a na-esi enweta ya)

Ọnụọgụ ndị na-eguzogide nrụrụ aka site na ezigbo ruo dị elu

Usoro usoro Kingrun

Ma e jiri ya tụnyere ụzọ ndị ọzọ e si emepụta ihe, ihe ndị a na-eme ka ihe dị n'ime ya na-enye uru ndị a:

1. Mepụta ụdị 3D dị mgbagwoju anya nke na-agaghị ekwe omume na mpụta ma ọ bụ imepụta ihe

Enwere ike ijikọta ihe na-ekpo ọkụ, etiti, ebe obibi, ihe mkpuchi na ihe ndị na-ejikọ ọnụ n'otu nkedo

2. Enwere ike itinye oghere n'ime nkedo anwụ

3. Ọnụego mmepụta dị elu na ọnụ ala dị ala

4.Nchedo siri ike

5. N'akụkụ kwụsiri ike

6. Achọghị igwe eji arụ ọrụ nke abụọ

Nye elu dị larịị nke ukwuu (ọ dị mma maka kọntaktị n'etiti ebe a na-ekpo ọkụ na ebe a na-esi enweta ya)

Ọnụọgụ ndị na-eguzogide nrụrụ aka site na ezigbo ruo dị elu

Nchekwa EMI na RFI dị mma