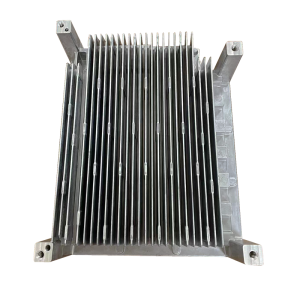

Heatsink a na-eji aluminom mee ihe nwere nku e si na ya pụta

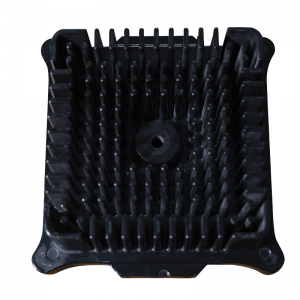

Ịkpụ ihe e ji akpụ ihe bụ usoro nrụpụta dị irè nke nwere ike imepụta akụkụ nwere ọdịdị dị mgbagwoju anya. Site na ịkpụ ihe e ji akpụ ihe, enwere ike itinye nku mmiri okpomọkụ n'ime etiti, ụlọ ma ọ bụ ihe mkpuchi, yabụ enwere ike ibufe okpomọkụ ozugbo site na isi iyi gaa na gburugburu ebe obibi na-enweghị mgbochi ọzọ. Mgbe ejiri ya mee ihe nke ọma, ịkpụ ihe e ji akpụ ihe anaghị enye naanị arụmọrụ okpomọkụ dị mma, kamakwa ọ na-echekwa nnukwu ego.

Uru nke die Cast Heatsink

Dabara adaba maka ngwaahịa dị iche iche.

Belata ọnụ ahịa nhazi.

Nyocha nke usoro ebu ọkachamara iji belata oge mmepe ngwaahịa ma melite ọnụego mmepụta ngwaahịa.

Igwe CMM akpaka zuru oke iji hụ na nha ngwaahịa ahụ ruru nkọwapụta.

Ngwa nyocha X-ray na-eme ka ọ ghara inwe ntụpọ ọ bụla n'ime ngwaahịa ahụ a na-atụba n'ime ya.

Mkpuchi ntụ ntụ na usoro ọkọnọ Cataphoresis na-eme ka a hụ na ọgwụgwọ elu ngwaahịa ahụ dị mma nke ọma.

Isi usoro nke extrusion mere nku + Die nkedo

Nku ndị a na-ewepụta site na iji ngwa ọrụ extrusion.

Ahụ aluminom nke a kpụrụ akpụ.

Ịkpụcha/ịkpụcha CNC/ịkpụcha/ịkpụcha dịka ọ dị mkpa.

Paịpụ okpomọkụ maka mgbakọ/tube ọla kọpa/tube ígwè anaghị agba nchara/skwọọ/ịchafụ iji nweta heatsink emechara.